SURFACE-FIRST™ MONITORING

Many environmental threats do not appear uniformly across water or infrastructure. Oil sheens, early-stage algal growth, and organic pulses often emerge or concentrate at the water surface first, before mixing, dilution, or downstream impacts occur.

Hawk sensors are designed around this reality, providing continuous, non-contact monitoring of the commonly unmonitored surface layer—on water, ground, and solid surfaces—to deliver earlier visibility and faster response.

ADDITIONAL MONITORING LAYER

Hawk sensors provide an additional monitoring layer for critical surface areas, complementing existing in-water instruments, sampling programs, and broader-area remote monitoring approaches.

This added layer delivers early, continuous surface visibility without adding maintenance complexity, operational burden, or disrupting established workflows—helping indicate when follow-up investigation or action may be warranted.

REAL-TIME DATA FOR ACTION

Hawk sensors deliver continuous real-time data and automated alerts—without physical contact, fouling, or drift. Data can be integrated into SCADA, control systems, and monitoring platforms to support timely, informed decisions.

This enables practical actions such as intake management, spill and leak response, public health protection, and treatment or operational adjustments for water systems, facilities, and critical surface assets.

Where Hawk Sensors Enhance Safety & Protection

On Water, Land & Critical Surface Assets

Hawk sensors are being developed for a range of applications where early visibility of surface-level environmental and operational risks is important. These include oil and fuel releases (spills and leaks), harmful algal blooms (HABs), and surface-associated organic matter (fDOM/CDOM).

By providing continuous, non-contact monitoring at the surface, Hawk sensors help identify emerging conditions that may warrant further investigation, sampling, or response. Monitoring data can be integrated with existing systems to support situational awareness, incident response planning, and longer-term trend analysis across municipal, industrial, and environmental contexts.

These capabilities support organizations responsible for protecting water quality, public health, and critical infrastructure by adding early surface visibility where traditional monitoring approaches may be limited.

If you work in one of the sectors below—or in another setting where surface-level monitoring could add value—we invite you to explore the application examples that follow or connect with us to discuss your monitoring challenges.

Principle of Operation

Hawk sensors utilize non-contact multispectral fluorometry, a technique that uses light to detect specific molecules based on their fluorescence properties.

Depending on the application, the sensors project pulses of ultraviolet (UV) or visible light onto the monitored water, ground, or solid surface, which can be more than 33 ft (10 meters) away from the sensor. When this excitation light

interacts with certain hydrocarbons found in crude oil and petroleum products; photosynthetic pigments in cyanobacteria, green algae, or select other microalgae; or fluorescent components within colored dissolved organic matter (CDOM),

it causes the emission of fluorescent light at distinct wavelengths.

The sensors then detect this fluorescence and measure its intensity, which is proportional to the amount of the target substances present—the greater the presence, the stronger the signal. This intensity measurement enables Hawk sensors

to not only detect the presence of contaminants, but also to provide an indication of the relative severity of spills, leaks, contamination, or blooms in real time.

When a user-defined intensity threshold is reached, the sensor activates an alarm for response. The relay output can also directly trigger external equipment, such as shutoff valves, pumps, or warning lights, supporting automated safety

actions or process adjustments where configured.

The sensor can continuously transmit real-time monitoring data to control systems, SCADA platforms, monitoring networks, or software applications via wired or wireless connections. This supports centralized oversight, trend analysis,

and predictive modeling, providing inputs for early detection and proactive mitigation efforts, as well as automated or manual corrective response.

In water monitoring applications, hydrocarbon contamination, harmful algal blooms (HABs), and dissolved organic matter (DOM) plumes typically first appear at or near the water’s surface, including intakes, where in-water sensing or

sampling may be impractical. By monitoring this commonly unmonitored but critical surface layer, Hawk sensors detect these threats at an early stage, enabling operators to take protective action—such as reducing intake flow rates,

switching to uncontaminated intake sources, or adjusting treatment processes—before contamination spreads deeper into the water column or enters the intake.

Related resource:

How surface monitoring, in-water sensing, and sampling work together in water systems:

Patented CFRS™ Technology

Powerful Non-Contact Monitoring Across Multiple Key Parameters

Multispectral Detection of Liquid Hydrocarbons, Harmful Algal Blooms & CDOM

Hawk sensors offer broad multispectral capability for detecting a wide range of liquid hydrocarbons and contaminants. This includes oils, fuels, and other petroleum products, produced water, blue-green (cyanobacteria) and green algae, select other microalgae, and colored dissolved organic matter (CDOM).

Hawk sensors primarily utilize ultraviolet A (UVA) excitation, a standard approach for non-contact hydrocarbon detection. UVA is well suited for general hydrocarbon monitoring applications and provides strong sensitivity across a wide range of crude and refined oils, from heavier fuel oils and lubricants to many midweight and lighter refined products.

In certain applications, particularly those involving very light or highly refined hydrocarbons present at trace levels, conventional UVA-only sensors may experience reduced sensitivity or may not reliably detect these products. For such specialized use cases, Hawk sensors are available with ultraviolet B (UVB) excitation, which maximizes sensitivity to lighter and very light hydrocarbons such as gasoline and naphtha. UVB configurations are typically used in targeted applications where detection of light refined products is a primary focus.

UVA excitation is also used to detect colored dissolved organic matter (CDOM), a naturally occurring organic material and key precursor to disinfection by-products (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs). Real-time CDOM monitoring supports early detection of organic surges and can inform DBP management strategies through source or treatment adjustments.

Hawk sensors additionally leverage multiple selected wavelengths in the visible spectrum to optimize sensitivity and accuracy for targeted algal pigments and corresponding blooms.

In some cases, Hawk sensors may be capable of detecting additional substances that exhibit suitable fluorescent properties, such as certain condensates, solvents, coolants, or fluids containing UV tracers or dyes. Feasibility depends on the specific product composition and application context.

Continuous Non-Contact HABs Monitoring: Chlorophyll, Phycocyanin & Additional Algal Pigments

Harmful algal blooms (HABs) are large accumulations of algae that can produce toxins, disrupt aquatic ecosystems, and cause problems for drinking water supplies, industrial operations, and recreational waterbodies.

BlueHawk Algae Sensors continuously monitor and quantify relative levels of targeted blue-green algae (cyanobacteria)—including both freshwater and marine species—green algae, and select other microalgae such as golden algae in waters by analyzing the levels of specific photosynthetic pigments within these organisms.

Each sensor is configured for the target algae and corresponding pigments. Chlorophyll, found in all algae, serves as a baseline measurement for overall algal activity. Additional pigments can be used for more specific identification: Phycocyanin indicates the presence and concentration of freshwater or marine cyanobacteria, while phycoerythrin is used to detect and quantify marine blue-green algae specifically.

By using a combination of chlorophyll and the additional pigments, BlueHawk Algae Sensors provide a more comprehensive picture of algal activity and type in the waterbody than common chlorophyll-only monitoring.

Additionally, a BlueHawk CDOM Sensor can be deployed to monitor colored dissolved organic matter in surface waters by measuring the level of its fluorescent components.

Hawk sensors’ non-contact detection method eliminates the need for physical contact with the water, resulting in low-maintenance operation by eliminating biofouling and drift.

Exceptional Performance: CFRS™ Technology for Reliable Detection on Water, Ground & Solid Surfaces

BlueHawk sensors’ unique and patented LED-based coaxial optical design offers significant advantages over conventional sensors. It allows for reliable monitoring of water and terrestrial surfaces such as concrete, metal, soil, and ice—including direct detection on equipment surfaces—with varied shapes and orientations. This makes BlueHawk well suited for monitoring flat and uneven surfaces, equipment with intricate geometries, and industrial, municipal, and natural water systems. They are also effective for detecting hydrocarbons in process waters, cooling waters, produced waters, stormwaters, and wastewaters.

CFRS sensors’ large lenses and apertures offer efficient light delivery and improved signal-to-noise ratio, boosting sensitivity to detect trace-level signals under appropriate conditions, while minimizing false alarms.

Continuous built-in self-diagnostics, light source status monitoring, and LED power compensation functions help maintain consistent performance across operating conditions.

High pulse rates enable BlueHawk sensors to operate at significantly higher sampling rates than many traditional sensors, making them ideal for monitoring choppy, turbulent, and fast-moving waters.

The result: BlueHawk sensors support reliable monitoring in applications where traditional methods may be limited.

Compact Design, Low Power Consumption, and Built for Tough & Hazardous Environments

Leveraging the advancements in optics and electronics, Hawk sensors achieve remarkable compactness, lightweight design, and minimal power consumption. This makes them ideal for deployment in space-restricted and power-limited environments, such as cramped sumps, remote monitoring stations, buoys, mobile platforms, and other battery- or solar-powered applications.

Hawk sensors feature IP68-rated standard enclosures, providing robust protection in demanding environments and resistance to temporary submersion.

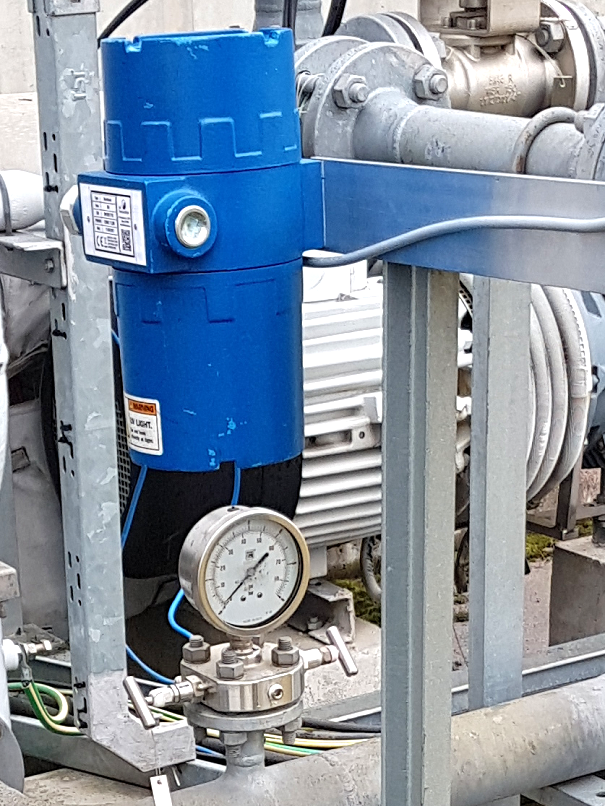

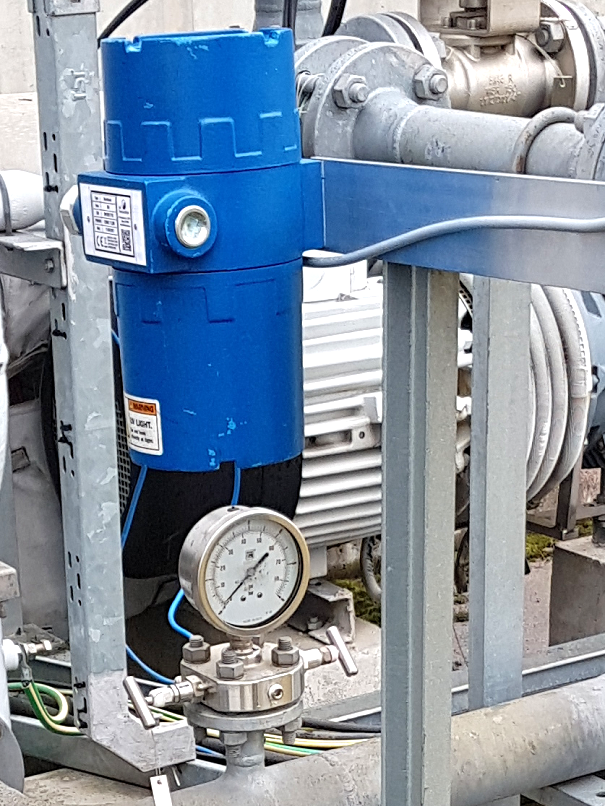

Optionally, HazLoc (Class I/II/III, ATEX) enclosures are available for deployment in hazardous locations with flammable gases, vapors, liquids, or combustible dust. This supports deployment in industries such as oil and gas, petrochemical, chemical, and mining.

Built for demanding environments, Hawk sensors support reliable, low-maintenance monitoring over extended operating periods.

Extensive Range & Broad Detection Angle: Flexible Deployment for Stationary or Mobile Monitoring

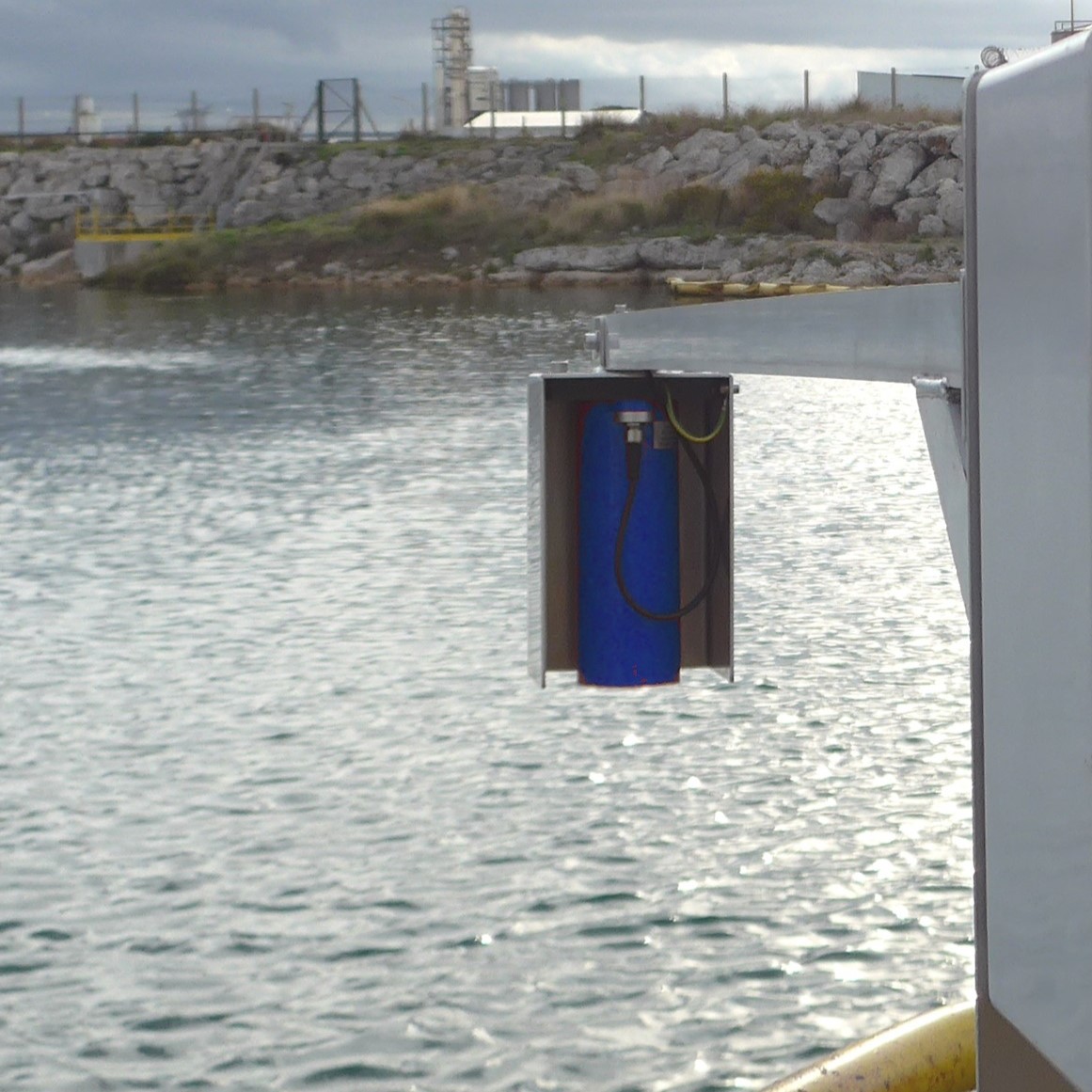

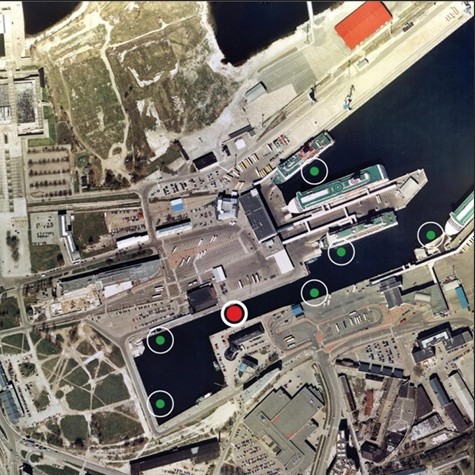

With a detection range of over 33 ft (10 m), BlueHawk sensors are designed to minimize installation and operational disruption. The sensors can be mounted on nearby or distant platforms like water intake towers, embankments, dams, piers, bridges, deep sumps, loading/unloading racks, storage tanks, and other structures within industrial facilities. They can also be deployed on vessels, vehicles, and aerial drones for mobile monitoring.

Hawk CFRS sensors are highly adaptable to varying surface distances, supporting reliable water monitoring in industrial settings and waterbodies with fluctuating water levels, such as tidal zones, reservoirs, canals, and intake structures.

A wide detection angle (±45°) expands deployment options in environments where perpendicular installation is difficult or impossible. This also allows pairing the sensor with a pan-tilt mount for continuous scanning of large areas and surfaces up to 1,600 sq ft (150 m²) from a single point.

Additionally, the broad detection angle enhances monitoring coverage on complex surfaces of intricate equipment and improves accuracy in dynamic environments such as turbulent or fast-flowing waters with constantly changing surface topography.

Real-Time Monitoring, Edge Intelligence, Flexible Connectivity, and Customizable Options

Hawk sensors are engineered for the demands of modern industrial and environmental monitoring. With robust real-time monitoring capabilities, Hawk sensors continuously collect up-to-the-moment data on hydrocarbon presence, algae blooms, and contamination events, and can transmit data or alerts as needed. This empowers users to track changes as they occur and support timely response to anomalies, while supporting regulatory compliance efforts.

Built-in edge computing enables each sensor to process and analyze data locally, right at the source. As a result, actionable insights—such as alarm threshold breaches—can be generated locally, even before data is sent to the cloud or control center. Edge intelligence not only reduces bandwidth requirements by transmitting only essential information and alerts, but also ensures immediate on-site notifications and can trigger external safety or other devices locally where configured, supporting rapid response to emerging issues. This approach delivers continuous, real-time data for accurate, up-to-date operational and environmental insights, while enabling immediate local actions and enhancing reliability and compliance with automated, traceable data collection.

Sensors can be configured remotely from your desk or control room. Versatile connectivity options—including direct wired connections, or wireless transmission via integrated cellular, satellite, or low-power wide-area network (LPWAN) modules—enable secure, reliable delivery of both continuous real-time monitoring data and actionable alerts. This edge-enabled sensor platform supports efficient data management, timely insights, and global accessibility.

Hawk sensors feature a comprehensive range of industry-standard interfaces—including RS-485 (Modbus RTU) / USB, 4-20 mA analog output, and SPDT relay contacts—for integration with SCADA, PLCs, and other industrial or environmental monitoring systems. Designed for flexibility, Hawk sensors can operate independently or as part of scalable, multi-sensor networks, ensuring compatibility with both modern digital and legacy analog infrastructures.

To further enhance functionality, Hawk sensors offer optional features tailored to specific needs. For example, the BlueHawk can be equipped with surface distance measurement to improve detection accuracy across its entire sensing range, especially in applications with widely fluctuating surface distances or water levels. Additionally, Hawk sensors can be fitted with a data logger for recording digital output, enabling historical data analysis even when offline from the main network.

BlueHawk™ & TinyHawk™ Sensors

Multi-Surface Monitoring for Hydrocarbons, HABs & CDOM

BlueHawk CFRS™ Family: Our Flagship Sensors

BlueHawk CFRS (Coaxial Fluorometric Remote Sensing) sensors are well suited for applications that require long sensing ranges or the ability to detect and monitor hydrocarbon spills, leaks, presence in water, and algal blooms over a wide range of sensor-to-surface distances. This makes them well-suited for non-intrusive monitoring at industrial facilities, on land, in turbulent, high wave, and large tidal water environments, and onboard drones, buoys, vessels, or vehicles. Additionally, BlueHawk can measure CDOM (colored dissolved organic matter) in water, and all BlueHawk sensors can be installed on pan-tilt mounts for large-area monitoring.

KEY SPECIFICATIONS:

Monitored surfaces: Calm to turbulent waters, dry and wet ground and solid surfaces

Detectable hydrocarbons: Wide range of liquid hydrocarbons from crude oil to refined intermediates and light, midweight, and heavy finished products—including fuel oils, lubricants, heating oils, hydraulic oils, diesel, jet fuels, avgas, naphtha, and gasoline—including hydrocarbons present in produced water

Detectable HABs: Freshwater and marine cyanobacteria (blue-green algae), green algae, and select other microalgae such as golden algae, using chlorophyll, phycocyanin, and phycoerythrin pigment level measurements

Detectable DOM: Colored dissolved organic matter (CDOM) in fresh and saline waters through fluorescent component measurement

Light source: LED with self-diagnostics and power compensation functions

Operational wavelength bands: UVA / UVB / Vis

Detection range: 0.7 to 33+ ft (0.2 to 10+ m)

Coverage: Up to 1,600 sq ft (150 m²) on pan-tilt mount. Effectively unlimited when mounted onboard a drone, vessel, or vehicle

Sensitivity: Sub-μm / sub-ppm, adjustable

Detection/installation angle: Up to ±45° from perpendicular to surface

Pulse rate: Up to 10 Hz, adjustable

Enclosure: IP68 standard, HazLoc (Class I/II/III, ATEX) optional

Size (Standard): Ø 4” x 9.4” (Ø 10 cm x 24 cm)

Weight (Standard/HazLoc): 3.0 lb / 10.8 lb (1.4 kg / 4.9 kg)

Power: 10–36 VDC, 2 W

Interface and Communication: RS-485 (Modbus RTU), USB; 4-20 mA, SPDT relay

Optional features: HazLoc (Class I/II/III, ATEX) enclosure, Surface distance / Water level measurement, Wired or Wireless data transmission and alerts, Stand-alone or Networked operation, Data logger

Skip form and download our general datasheet directly below.

Need an industry-specific datasheet? Contact us.

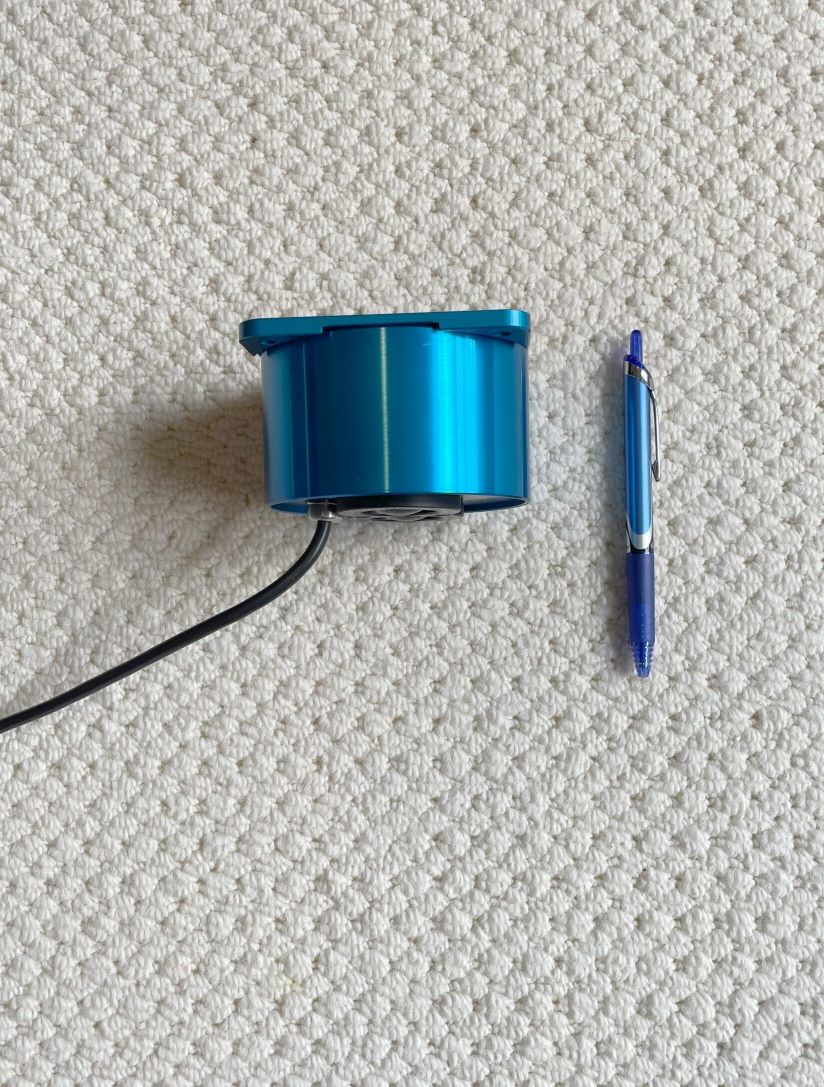

TinyHawk: Compact Design, Advanced Performance

Optimized for closer-range hydrocarbon monitoring (up to 10 ft / 3 m) on static surfaces, TinyHawk combines reliability with minimal size, weight, and power consumption in a cost-effective package.

KEY SPECIFICATIONS:

Monitored surfaces: Static surfaces such as concrete, metal, soil, calm, level water, etc., where the distance between the sensor and the surface remains relatively constant

Detectable hydrocarbons: TinyHawk can detect a wide range of liquid hydrocarbons from crude oil to refined intermediates and light, midweight, and heavy finished products—including fuel oils, lubricants, heating oils, hydraulic oils, diesel, jet fuels, avgas, naphtha, and gasoline—including hydrocarbons present in produced water

Light source: LED

Operational wavelength bands: UVA / UVB

Detection range: 0.7 to 10.0 ft (0.2 to 3.0 m)

Sensitivity: Sub-μm / sub-ppm, adjustable

Detection/installation angle: Up to ±45° from perpendicular to surface

Pulse rate: Up to 10 Hz, adjustable

Enclosure: IP68 standard, HazLoc (Class I/II/III, ATEX) optional

Size (Standard): Ø 4” x 3.5” (Ø 10 cm x 9 cm)

Weight (Standard/HazLoc): 1.5 lb / 5.5 lb (0.7 kg / 2.5 kg)

Power: 12–35 VDC, 1.5 W

Interface and Communication: RS-485 (Modbus RTU), USB; 4-20 mA / SPDT relay

Optional features: HazLoc (Class I/II/III, ATEX) enclosure, Wired or Wireless data transmission and alerts, Stand-alone or Networked operation, Data logger

About PhotonTec™

Smart Sensing for Safer and Cleaner Tomorrow™

PhotonTec’s founders bring over 30 years of optical sensing and imaging expertise to your industrial and environmental monitoring needs. Based in Atlanta, GA, we specialize in advanced non-contact multispectral fluorometric sensors for oil/fuel detection and HABs monitoring, utilizing patented CFRS™ technology and deep knowledge in optical and photonic systems. Our experience spans a range of applications—from IR sensing to 3D machine vision and AI-driven inspection systems.

We provide comprehensive sales, application support, and expert technical services for the Hawk series sensors, supporting smooth deployment and reliable performance across diverse monitoring environments. Our customer-focused approach is centered on delivering tailored solutions to meet specific operational requirements.

Manufactured at ISO 9001:2015 certified facilities in Europe, our sensors combine state-of-the-art optics and electronics, designed to deliver the reliability and precision demanded by leading organizations worldwide.

Our leadership actively contributes to industry best practices through participation in the American Water Works Association (AWWA) Real-time Water Quality Monitoring Committee (RWQMC). We also host a professional LinkedIn community focused on non-contact water monitoring for hydrocarbons, HABs, and CDOM, supporting knowledge-sharing among utilities and environmental professionals.

Trademarks used herein are the property of their respective owners.

We’d Love to Hear from You

We’re here to help. Whether you’re interested in Hawk sensors’ features, exploring applications for your operations, requesting product documentation, scheduling a product demonstration, conducting feasibility tests with your samples, or making press inquiries—we’re ready to answer your questions.

Contact us using the form below or by:

Phone: +1 (770) 366-4137

Email: info@photontec.net

LinkedIn Community (Hosted by PhotonTec):

Non-Contact Water Monitoring: Hydrocarbons, HABs & CDOM

https://www.linkedin.com/groups/16073024/

Website: www.photontec.net

Location: Atlanta, GA, USA (Eastern Time)